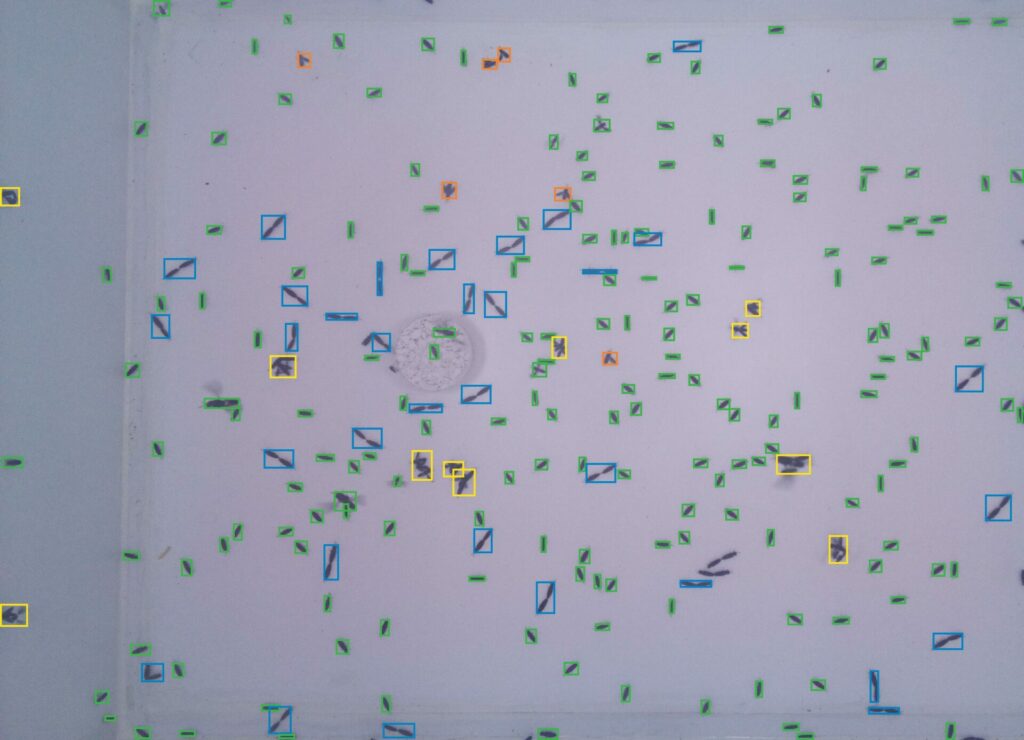

A modular smart camera system was used to implement real-time process monitoring of an industrial insect farm. The recorded images are segmented, classified and then analysed using neural networks in order to extract important process parameters. Direct feedback on mating activity makes it possible to react to fluctuations in real time rather than with a two-day delay. Only through this rapid feedback is it possible to intervene in the ongoing process before an unavoidable collapse in egg laying occurs. This slump in egg laying would otherwise lead to an unavoidable fluctuation in all further process steps and ultimately also in the overall capacity utilisation. As industrial breeding is carried out in batch operation, this results in major complications. In addition, these fluctuations can lead to high economic risks for the operators, as they sometimes have long-term purchase agreements that have to be fulfilled. Such fluctuations must therefore be avoided at all costs.